Automation Engineer

On this page

- What's it like to be an Automation Engineer?

- How to become an Automation Engineer

- Latest Automation Engineer jobs

- Top skills and experience for Automation Engineers

- Automation Engineer role reviews

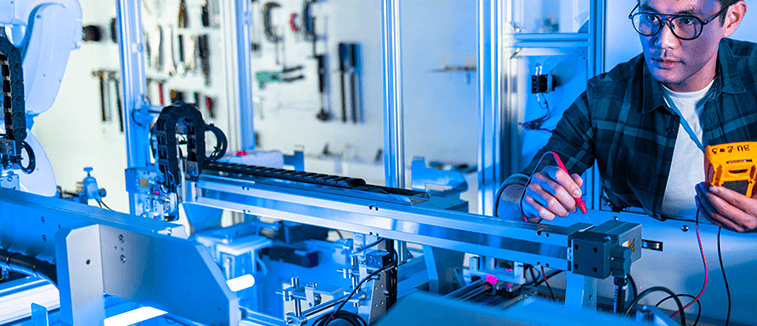

What's it like to be an Automation Engineer?

Automation Engineers are involved in every stage of automation design and programming – from conception to testing and troubleshooting. This field requires collaboration among cross-functional teams including electrical and mechanical engineers in creating innovative solutions which streamline operations and increase work efficiency. Automation Engineers play a pivotal role in the manufacturing and industrial sectors by designing and implementing automated systems. Utilising their technical expertise, these experts use solutions designed to optimise processes, increase productivity, and ensure high-quality outputs across various industries such as manufacturing, energy, automotive and pharmaceuticals.

Tasks and duties

- Designing and developing control systems for automation processes.

- Programming and configuring programmable logic controllers (PLCs) and human-machine interfaces (HMIs).

- Collaborating with electrical and mechanical engineers to integrate automation solutions.

- Conducting tests and inspections to ensure proper functionality and performance of automated systems.

- Troubleshooting and resolving issues in automation systems to minimise downtime.

- Developing and implementing safety protocols and ensuring compliance with industry standards.

- Documenting technical specifications, system designs, and maintenance procedures.

How to become an Automation Engineer

To pursue a career as an Automation Engineer, you typically need a relevant degree and practical experience in automation engineering.

- 1.

Complete a bachelor degree in automation engineering, electrical engineering, mechatronics engineering or a related field.

- 2.

Gain practical experience. Seek internships or entry-level positions in automation engineering to gain hands-on experience with automation systems, control programming, and troubleshooting.

- 3.

Develop technical skills: Enhance your skills in automation technologies, control systems, PLC programming, robotics, and supervisory control and data acquisition (SCADA) systems. Stay updated with the latest automation software, programming languages, and hardware platforms commonly used in the industry.

- 4.

Consider acquiring certifications. To gain more knowledge and credentials in the field, consider pursuing certifications such as Certified Automation Professional (CAP) or Certified Control Systems Technician (CCST).